Grow3D

Year

2017

Client

HTW Dresden

semester project

semester project

Team

no Team

My semester project in the module “Opportunity” by Prof. Elke Mathiebe was called “Grow3D”. It emerges as a groundbreaking project within the realm of bicycle saddle design, seamlessly integrating the principles of nature into a fully 3D-printed, one-part, one-material product. Conceived as a further exploration of the overarching theme of “Forms of Nature” of an older master’s semester project, Grow3D reinterprets the traditional bicycle saddle.

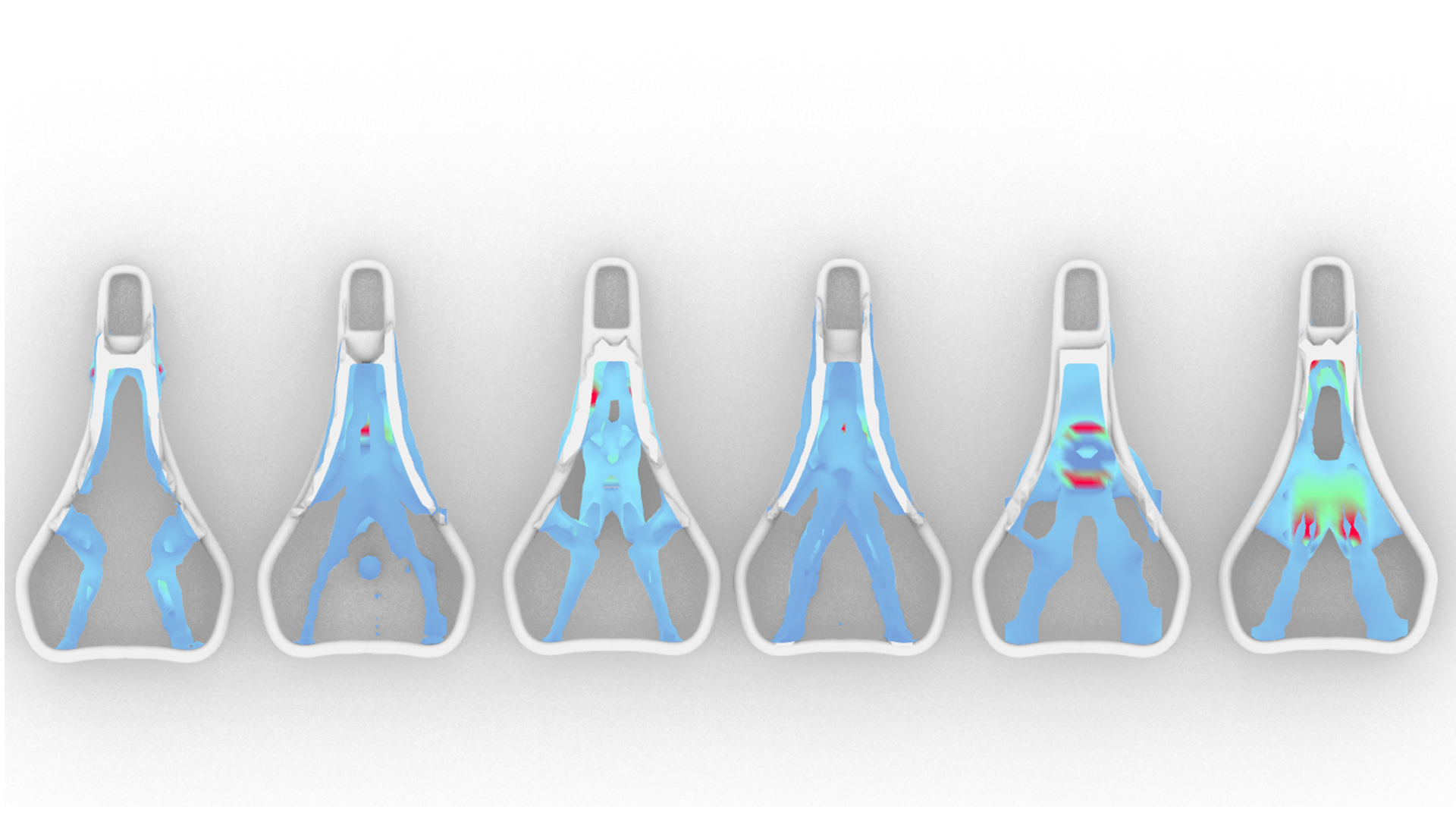

In nature, structures don’t assemble in parts; they grow and transform. Grow3D embodies this philosophy by offering a heterogeneously structured saddle that provides a unique blend of flexibility and stability, meticulously tailored to the rider and their bicycle. Leveraging the rapid progress in additive manufacturing, the design explores new shapes and structures using generative algorithms. The SLS-printing technology allows for the creation of structures with specific properties in a single material, without the need for removing complex support masses.

The super lightweight design of Grow3D is a testament to the possibilities that arise when designers embrace innovative technologies. By skillfully adapting material strengths in different areas, the saddle achieves a balance between flexibility and hardness. Parameters such as body weight, hip width, driving styles, and bicycle model, analyzed through algorithms, contribute to the generation and printing of a customized saddle.

Imagine a future where purchasing a bicycle saddle is a personalized experience. In a bike shop, your body measurements are captured by a sensor-equipped saddle. Additional personal preferences, such as riding styles, bicycle models, and colors, are inputted. These data parameters fuel the algorithm to generate a unique design. The 3D data is then sent to the printing facility, producing a personalized saddle that is shipped directly to the customer and ready for immediate installation.

Imagine a future where purchasing a bicycle saddle is a personalized experience. In a bike shop, your body measurements are captured by a sensor-equipped saddle. Additional personal preferences, such as riding styles, bicycle models, and colors, are inputted. These data parameters fuel the algorithm to generate a unique design. The 3D data is then sent to the printing facility, producing a personalized saddle that is shipped directly to the customer and ready for immediate installation.